A Tightening Solution for Tight Connections: Understanding 3/8-18 NPT and the Importance of Tap Drills

Let’s face it, sometimes you need a really secure connection. Those situations where even a slight wobble or looseness can lead to unwanted leaks or malfunctions—those are the moments where precision fitting comes into play. And when it comes to connecting pipes and components in industries like manufacturing, plumbing, and engineering, nothing beats the power of reliable threads.

Specifically, 3/8-18 NPT (National Pipe Taper) fittings offer a robust solution for joining pipes and tubes. The “NPT” part stands for “National Pipe Taper,” which means the thread form is specifically designed to ensure a tight seal without excessive pressure on the fitting itself.

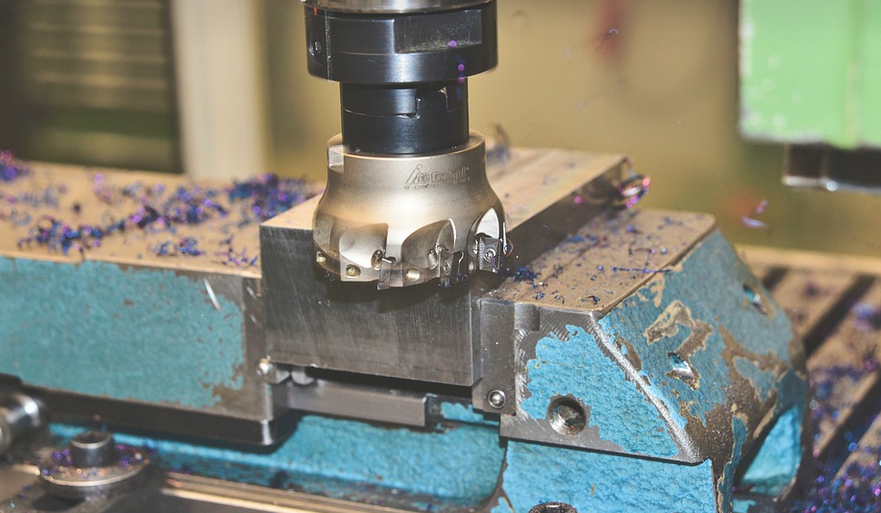

Now, entering the world of threading requires more than just knowing what’s inside; you also need the right tools. A tap drill is your key to achieving precise and efficient threads for 3/8-18 NPT fittings. Think of it like a tiny but mighty machine that can smooth out imperfections and take those rough edges off your threaded components.

Why Choose Tap Drills for 3/8-18 NPT?

Tap drills are not just any old drill; they’re designed specifically to create threads – the foundation of secure connections. They offer several advantages that make them a reliable choice for working with NPT fittings:

– **Precision:** Tap drills have small, sharp cutting edges and precise flutes, which allow for controlled and consistent thread creation. This ensures optimal contact between the drill bit and the material being drilled, producing smooth, functional threads.

– **Durability:** Tap drills are made from high-quality materials like steel, specifically engineered to withstand the demands of threading. This translates to longer lifespan and reduced maintenance needs.

– **Efficiency:** Tap drills are designed for fast, smooth drilling, which saves time and effort in the long run. Their self-centering capabilities reduce slippage during operation, further speeding up the process.

– **Versatility**: Tap drills come in a variety of sizes, each capable of creating threads on different diameter pipes and tubes. This adaptability means you can use one tool for multiple applications, streamlining your work flow.

Getting Started with Your Tap Drill: A Step-by-Step Guide

Here’s a comprehensive guide to help you navigate the process of using a tap drill for 3/8-18 NPT fitting:

- Preparation: Before starting, ensure you have all the necessary tools and safety gear. Familiarize yourself with the drill’s operation and understand its capabilities.

- Thread Guide: Use a thread guide or tap gauge to ensure accurate alignment of your drill to the NPT fitting. This helps maintain correct thread pitch.

- Drilling Technique: Start by applying light pressure on the tap drill, slowly rotating it until it reaches the desired depth. A steady pace and controlled motion are key for a clean cut that avoids excess material being removed.

- Clean Up : After drilling, remove any debris from the thread created to ensure smooth operation of your fitting. This can be done by using a small brush or compressed air.

Using a tap drill is an efficient way to create accurate and strong NPT connections. It’s easy to learn and offers a reliable solution for those demanding applications.

Beyond the Basics: Advanced Tap Drilling Techniques and Considerations

While the basics of using tap drills are straightforward, there are some nuances worth exploring to further maximize their effectiveness:

– **Speed Control:** The drilling speed directly impacts the quality of the threads. Too fast, and you risk overheating the metal, creating potential damage or inaccurate cuts. Too slow, and the drill may struggle to penetrate the material effectively.

– **Coolant Use:** Some materials require a cooling compound when drilled with a tap drill to manage heat and prevent burrs. This is especially important for softer materials that are more prone to overheating.

– **Different Drill Bits:** Tap drills come in various sizes, each designed for specific diameter threads. Choose the right size based on your NPT fitting’s dimensions for optimal results.

Safety First: Essential Precautions For Using a Tap Drill

Using a tap drill safely and effectively is paramount to avoiding injury or potential damages. Here are essential precautions:

– **Eye Protection:** Wear safety glasses when drilling to prevent debris from flying into your eyes.

– **Ventilation:** Ensure good ventilation while drilling, especially in enclosed spaces. This prevents the accumulation of dust and fumes that can be harmful if inhaled.

– **Proper Work Environment:** Work on a stable, well-lit surface with ample space for your drill to perform optimally without unnecessary movement or interference.

Conclusion: Tap Drills: The Heart of Accurate 3/8-18 NPT Fittings

Tap drills are an essential tool in any workshop or work environment that involves working with NPT fittings. They empower you to ensure proper threading for secure connections, saving time and effort. With a little practice and these guidelines, you can confidently tackle even the most demanding threading tasks.